MINE PLANNING AND SCHEDULING – SMART PRACTICES FOR IMPROVING SPEED AND ACCURACY TO ACHIEVE OPERATIONAL EXCELLENCE

INTRODUCTION:

Strength of a building depends on its strength of its foundation. Same is true for mining as well. As the foundation of all mining activity – a mine plan – most accurately reflects the real-time reality of the geological structure in the ground, the process capabilities and the economic unpredictability of demand and commodity markets; which results in a productive, predictable and profitable system within mining structure.

To optimize mine profitability, planners and schedulers are under constant pressure to create mine plans that are as accurate as possible and optimize production at all stages, from mine to market.

To ensure accuracy, planners and schedulers must account for a staggering array of variables, including:

- Geological samples and data from the mine

- Production capacity of each stage of the process

- Available equipment, machinery and manpower

- Sales demand and commodity prices

- Production cost assumptions

- Health and safety of workers

Traditionally, the time and resources required to continually collect this data, model and remodel scenarios, build and adjust mine plans, and plan out the effects on scheduling, has meant that no one could keep pace with the reality of what’s happening in the ground. Even the best mine plans were still full of inaccuracies and best guesses based on past experience, not quantifiable data. This resulting gap between a mine plan and reality is where costly surprises creep in to negatively affect production schedules, output, and ultimately, mine profitability.

The goal of good mine planning and scheduling is to fully understand the mine planning process, account for all significant variables as accurately as possible, decrease the time between geological sampling and mine plan re-modelling, minimize production costs, optimize output taking into account demand and commodity prices, and free mine engineers to focus on more strategic objectives such as continual improvement and operational excellence.

SMART PRACTICES OF MINE PLANNING AND SCHEDULING:

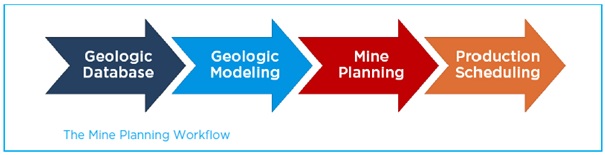

1. Understanding the Mine Planning Process – It may seem obvious, but to implement best practices, one needs to understand the mine planning process first. Each mine is different, but in general, mine production plan follows a fairly linear workflow. Followings are the steps:

- Gather drill hole and mine survey information to measure the geological structure. Sample the chemical analysis of the deposit.

- Create a geological model of the structure and chemistry from the data. Define the resource based on mining constraints.

- Design three-dimensional mining blocks which reflect the ground control plan and are of a size to provide sufficient resolution for mine scheduling.

- Estimate the resource quantity and quality contained in the mining blocks and use the data to produce a planned production schedule based on mining constraints.

Optimizing the plan typically require completing multiple plan scenarios. Having an efficient, integrated and streamlined process will reduce the amount of time required to complete a mine planning scenario. Additionally, the process should be repeated as new geological information becomes available to ensure any mine plan assumptions reasonably reflect actual field conditions. Inaccurate geological models will introduce errors into the downstream mining plans which can result in surprise cost increases and revenue reductions.

2. Identifying Planning Process Bottlenecks – All stages of the mine planning process, and technologies used to plan and schedule, should be analyzed paying close attention to where potential bottlenecks can form. Quick wins may be realized by focusing on the process first. A good place to start is looking upstream to areas in the process that are constrained by input.

For example, short term engineers can experience long wait times while interrogating the most current geological model. Geological models are usually extremely large, and an interrogation process that evaluates the entire model, rather than the small short term plan area, can be very inefficient. Through a simple process change, engineers can interrogate smaller portions of the larger model and prioritize the analysis, greatly improving the speed to production.

Bottlenecks are common when data must be shared between two processes that use different, stand alone applications. Transferring data in and out of these disparate applications adds complexity to the process. For example, some mines export mining blocks to Microsoft Excel to perform mine scheduling. Once the schedule is completed, they manually create plan progress maps in their CAD system. Through the use of an integrated system, construction of a graphical plan progress map could be automated, eliminating many hours of manual CAD work. Of course, there are always instances where data needs to be transferred to other systems, but selecting a system with modern plug-in architecture and open data will streamline the process.

Some bottlenecks may require a change in technology. Many miners are continually bumping up against constraints in some mine planning solutions. Some mines may maintain two geological models primarily because of a constraint on model size set by the planning application. They create a short term model at a higher grid resolution to meet the requirements for accuracy in short term planning, and then create and maintain another lower resolution model for longer range plans. Maintaining two identical models adds significant time and complexity to the modelling and interrogation process. Implementing a solution that would allow creation of a geological model of sufficient resolution for the short term model, but applied to the long term area, would greatly streamline the process and reduce the time to model.

3. Improvement of Accuracy in Geological Modelling – Streamlining the process cannot come at the expense of accuracy. Accuracy still remains the primary goal of all stages of the planning, scheduling and production process. To highlight this importance, take this example: Underestimating coal thickness by 6 inches over an area as little as 11 acres will result in a planned production shortfall of one unit train. If coal is selling at USD 50/ton, this would result in USD 500,000/- of revenue the mine will never realize.

Accuracy has implications across the entire production stream. Improving the accuracy of geological modelling increases the confidence in the mine plans to meet quality and quantity specifications on upcoming shipments. Accurate mine plans enable engineers to accurately predict when a significant multi-million dollar capital investment in new equipment would be required due to upcoming increased overburden volumes and sales volume. Getting this wrong can be catastrophic. If equipment is undersized, the company will have invested millions of dollars on equipment that cannot meet sales targets and perhaps lose millions more in penalties for not meeting customer demand in contracts. Options to make up lost production could force the company to buy on the commodities market and perhaps sell at a loss and/or purchase and commission additional unplanned equipment. Both solutions will at best reduce profits and may potentially make the operation completely unprofitable.

Improving accuracy in mine planning requires continuous improvement to the geological model, the foundation of the mine plan. Incorporating new mine data into the geological model will help decrease the variance between planning and actual production. What is planned will more closely reflect what is actually being produced. Excellence at this stage is critical to the viability of the mine, particularly in difficult economic times.

4. Accelerate Data from Field to Plan – Planners typically receive new geological models after a planned drilling season. Drill hole information is accumulated throughout the drilling season, and as the mine advances more data is gathered either through production drilling just ahead of operations or survey data collected by GPS systems. Planners can’t use new data if it is not reflected in the geological model, and geologists may only update the geological model at the end of exploration drilling if the modelling process is complex and labour intensive. Decreasing the time between the collection of the most current geological sample data and its reflection in the mine plan improves mine planning accuracy and ensures plans have the least amount of variance from reality.

Reducing the time between field sampling and model development allows multiple models to be created on the fly as new drill hole and quality data is received. Geologists are able to quickly analyze the effect of the additional drilling on the model and continually keep the geological model updated for mine planning. Accuracy is increased through a higher resolution model, which reflects measured data more closely.

Because geologists have more accurate models in less time, they can spend more time optimizing the exploration drilling plan. Through this exercise companies can reduce the number of planned exploration holes for the next drilling season. Increasing geological model accuracy and resolution can also eliminate the cost of drilling pilot holes in areas where infill drilling is performed to get supplemental coal quality data. Savings in drilling costs alone have been shown to more than offset the cost of mine planning software. With a cost savings of about USD 1,650/- per hole, that can add up to a significant reduction in drilling costs.

| Real World Example: Data Acceleration:

A mining operation was encountering water bearing sand zones, which were impacting shovel production and ground control. Because of the effort required to model the sand units, they were not modelled and the shovel would explore for the zones during operations. Exploring for problem zones with the shovel posed a significant risk of getting the shovel stuck in the sand or, worse, a highwall slope failure resulting in an unproductive shovel, which would severely impact coal production. The inability to model and effectively plan resources has significant adverse consequences. Consider the following to understand the impact:

Improving geological model turnaround and accuracy provided geologists time to model the non-coal, water bearing sand zones in a more cost effective manner. Once these zones were identified, shovel bench plans were developed to efficiently work in these difficult areas and communicated to operations. Streamlining the workflow gave engineers more time to get out of the office and get experience in field management roles where their analytical skills improved the operational workflow and the quality of daily decisions made in the field. |

5. Create & Analyze Multiple Scenarios – Optimizing the mine plan can require completing multiple plan layouts and schedules, examining the results and choosing the most cost effective scenario. Having an efficient, integrated and streamlined process will reduce the amount of time required to complete multiple mine planning scenarios. This process should be repeated as new geological information becomes available to ensure mining plan assumptions still reasonably reflect actual field conditions. Inaccurate geological models will introduce error into the downstream mining plans, which can result in surprise cost increases and revenue reductions to the operation. Incorporating the latest information into the geological model improves the accuracy of the mining plans. The reduction in time to develop mine plans results in better decision making through the ability to compare multiple mine plan scenarios simultaneously.

6. Combine Short & Long Range Models – A major improvement in geological modelling process flow can be made by combining both short and long range model areas into one model with a standard grid cell size. Eliminating the need to build more than one geological model and increasing automation can reduce model building time by 50-75 percent.

7. Integrate Planning & Scheduling – If an organization is running multiple software solutions for mine planning and scheduling, best practice would be to implement a single, integrated solution built with efficiency in mind. Integration will enable process improvements and shorten geological modelling and mine planning turn-around times, thus providing the ability to develop more accurate and optimized mine plans.

Using an integrated mine planning and geological modelling system will also improve the process flow. Rather than exporting block resource estimates to another scheduling package or Excel, scheduling can be completed in a single mine planning system. Plan progress map generation can be automated when a scheduling system is integrated with the CAD system. By implementing this change, time to complete long range mine plans can be reduced by 40-60 percent.

8. Addressing Complex Geological Areas – Often, the inability to model geologically complex areas can result in reduced equipment productivity, lost resources and reduced mine life. Make sure your modelling and planning technology can handle geologically complex areas. This should include the ability to define interval relationships, pinching and washout controls and the incorporation of field survey information. Models should be able to handle complex interval splitting and faulting, while honouring drill-hole information.

Mining the Complex: In one example, exploration drilling revealed a geologically complex area within the mine site. Typically two coal intervals were being modelled and mined in the planned and active operations. The geologically complex area showed eight coal units, which were splits from the two main coal intervals. Adding to this complexity in the coal formation was the presence of a sand channel unit, which presented a significant ground control risk to the mining operation.

Prior to implementing a robust geological modelling system, this complex area was mined around, because the existing modelling system could not effectively and confidently model and plan mining in this area. As a result of the improvements made in the geological modelling and mine planning system, the area was modelled and multiple mining scenarios developed to address the challenges of the area. Coal reserves that were previously avoided due to geological anomalies are now part of the mining plan, increasing the available reserves and extending the mine life.

9. Focus on Operational Excellence – Improvements in the process flow results in both direct and indirect benefits to the operation. Faster geological modelling and mine planning provides significant direct benefits in the form of cost savings and increased productivity. Also to be considered is the time freed for skilled engineering staff to focus on important, organization-wide initiatives such as continuous improvement and operational excellence projects.

With greater efficiency achieved through process improvements, mining organizations can reap significant benefits by focusing freed resources on continuous improvement and operational excellence. Freeing up engineering resources from this cumbersome process can result in exponential payback as they re-energize their focus on continuous improvements throughout the mine.

CONCLUSION:

By deploying best practice mine planning, scheduling and process improvements, mines will reap direct and indirect cost savings, and become more productive, predictable and profitable. Each mine is different, but key to deploying best practices is the use of a modern integrated mine planning and

Scheduling solution that can keep pace with the incoming mine data, ensure accuracy, accelerate mine modelling and plan output, facilitate information sharing, enable the mining of complex geographic areas, and free up valuable human resources to focus on continual improvement and operational excellence.

Very interesting and insightful article! Thanks.

A very good job done, very educative information for starters

Hi,am pleased to have this info!am formulating a small scale copper mine and I need your help.kindly furnish me with More info so this grows into a big mine.I am a starter in need.

Very interesting article. This will surely help the miner as well as geologist to understand the depth of their work.

I had to understand mine planning during my exams and I have been able to understand it pretty quickly after reading this article.

Thank you so much!

its wonderful i like it

Very well explained.